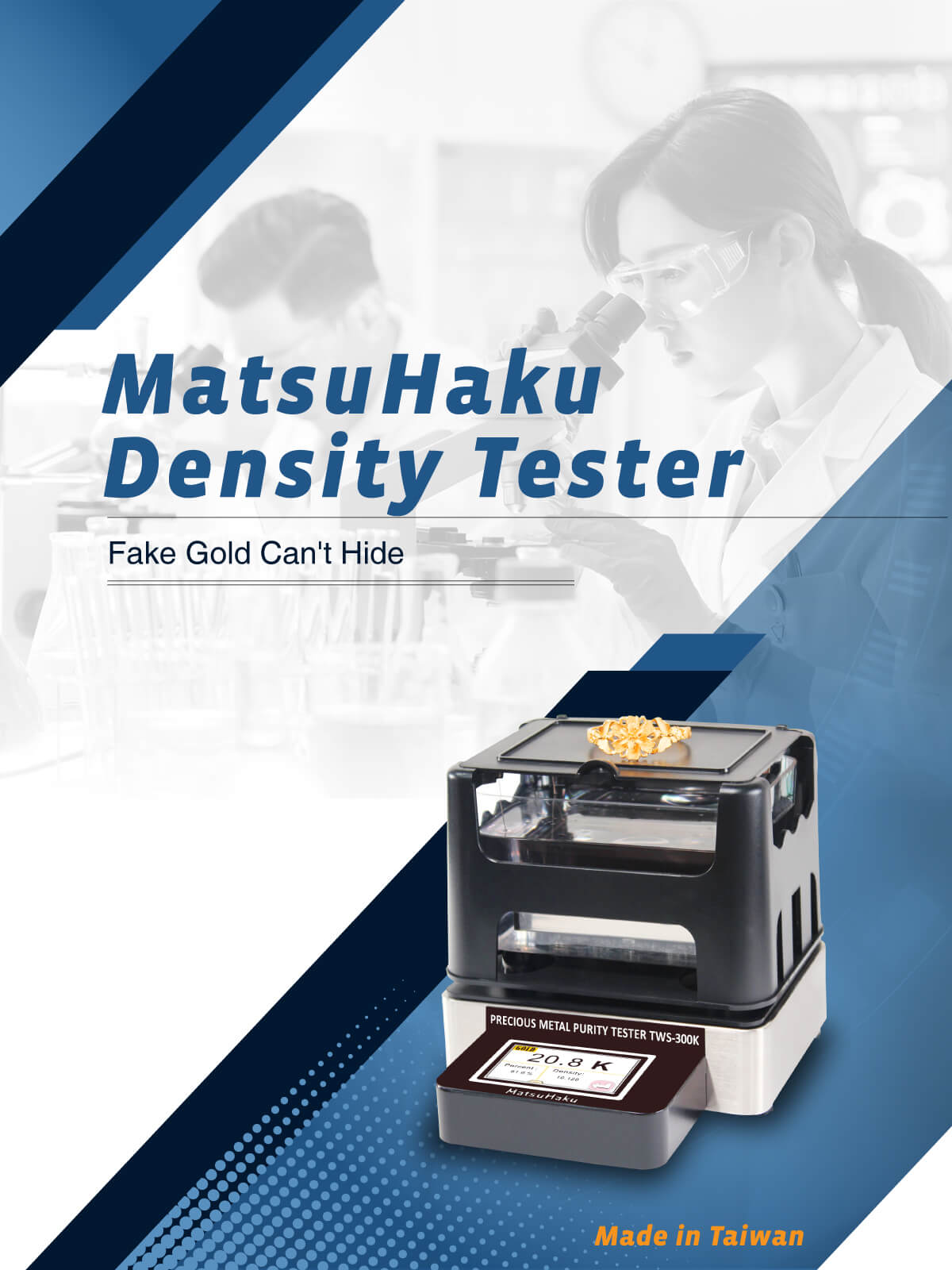

About Us

GROUP PROSPERS ENTERPRISE CO., LTD. own apparel brand 【MATSUHAKU】the expert of density tester manufacturer from Taiwan. Committed to manufacturing various professional instruments which meet the latest international norms (ASTM, ISO, GB/T, JIS), can test gold, rubber, film, oil ring, alkaline solution, ceramic, powder metallurgy, EPDM, refractory, etc., and is inducted into Precious Metal, Solid, Liquid, Powder, Porous, and Multi-function Series.